Póvoa de Santa Iria and HyChem share a history that deserves to be explored. Both evolved in the past 90 years to reach the hights they now hold in the region and in the country’s economic landscape.

The origin of the brine ponds, extinct on the second half of the last century after being detrimental for the wealth of Póvoa, is lost in memory. However, archaeological discoveries of artefacts from the prehistory age go back to the Palaeolithic; there are some important roman trace elements that suggest the navigation of Tagus River and human occupation of the area; and some remains of the exploration of brine ponds go back to the first dynasty.

The Morgado da Póvoa, which developed from Quinta da Piedade, flourished with the extraction of salt from the waters of the Tagus and, consequently, various families earned a living from the saline activity, that for centuries marked the Riverside life.

The agriculture (vineyards, olive groves, cereal cultivation), the fishing, river transports, and the work in brine ponds and tells gave employment to the habitants of Póvoa de São Martinho, seventh feudal lord from whom the location took the name for more than three centuries.

The industry, even so, set itself early. After the opening of the first section of the railway (1856), between Lisboa and Carregado, the Póvoa’s factory was installed in 1867 (chemical fertilizers) and, in 1877, the Companhia de Moagens de Santa Iria (cereal grinding), which contributed heavily for the industrial character that the site would assume in the future.

During the settlement of a small soda ash factory, Póvoa de Santa Iria was nothing but a village of few houses. There was no electricity, no church, no pharmacy and no water facilities other than a well. The centre was the junction point between the national road and the railway station.

However, that factory, a group of constructions laid on a green pine stake, often flooded by the Tagus’ floods, where a bloodthirsty soda ash was manufactured, wasn’t a big deal either.

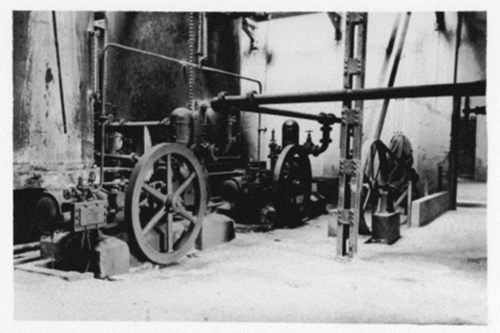

It all started with the World War I, or better, slightly before it hatched, in 1914. A Southern American country ordered from Germany the necessary equipment to install a small factory of soda ash, by the Solvay process, the only one applied in the World so far that had replaced Leblanc’s process.

At the time, the technology for the process was in the hands of the Belgian Company Solvay et Cie., of its branches and some associates. The secret was so well-kept that the German manufacturer of the ordered machinery had to resort to the only documentation to which he had access. That was how, based on the A. Schreil Treaty (1905), he built devices then already surpassed.

When the German ship, which carried that equipment destined to South America, entered Atlantic waters, the World Conflict started. In order not to be captured by the English, the ship took refuge on the Tagus, later ending up to be apprehended by the Portuguese Navy when our country entered the War.

Portugal lived a big soda ash and caustic soda shortage era during the World War I. It was, possibly, this lack of products that reminded people of the machinery that had stayed here. Among them was a French citizen, R. Touzet, who decided to acquire the equipment and build the factory in Póvoa de Santa Iria.

It was “The Old Factory”, whose construction will have been concluded by the 1920’s. Of those buildings there are still, in some places, the green pine stake, preserved until today by the salt water present underground.

The undertaking promoters did not succeed. The German machinery was obsolete and the ones in charge neither knew the manufacturing process, nor had counselling, hence the factory’s immobilization happened not long after.

In the early 1930’s, the director of Companhia Industrial Portuguesa (CIP), Lopes Raimundo, also Industrial Chemistry professor in Instituto Superior Técnico, thought he could start to make the factory work.

CIP acquired, then, the society and from the first tests resulted in a few tons of soda ash. Terrible quality, it’s true, but it was Soda! And it was enough to arouse interest in Manuel dos Santos Mendonça and of he’s represented firm in Portugal, Solvay et Cie.

At the same time of its European expansion, Solvay felt it was time to intervene and also be present in Portugal. In June 1934, two Solvay representatives – Philippe Aubertin and Barão Gendebien – closed a deal related to a new firm creation with the CIP representatives, where they committed to reduce the industrial cost and to reach an annual production of 6000 tons of soda ash.

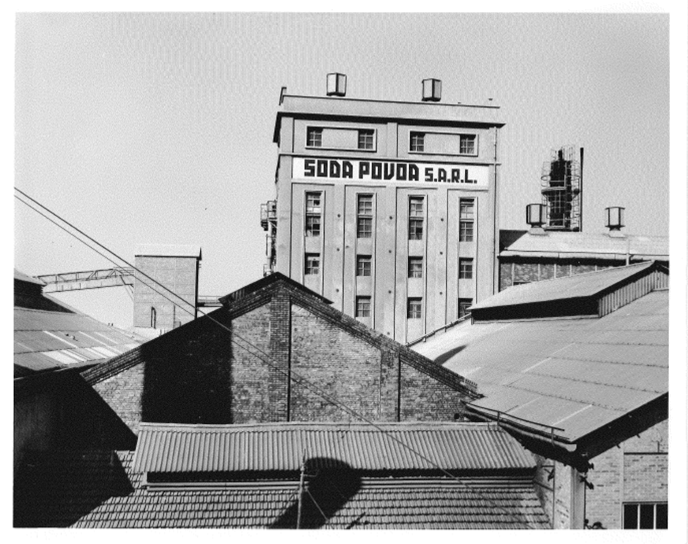

On September 20, 1934, Soda Póvoa was born, with a share capital of 500 thousand escudos. The notarial instrument of the company’s formation was drawn up at the 12th Notary Office of Lisbon, situated in Rua de S. Julião, and the bylaws published in the September’s twenty second Government Gazette - III Series.

Already in August that year, Clément Dumoulin had arrived in Portugal with his family. He had come to assume the factory’s management and become the main pioneer of its expansion.

The new firm adopted the designation “Soda Póvoa” for obvious reasons: to match the name of the product to be manufactured (Soda Solvay) with the name of the place where the factory was installed (Póvoa de Santa Iria).

In early 1934, Soda Póvoa effectively takes possession of the factory’s premises and begins the epic journey of the company.

In the beginning, many hardships: ammonia rejection from all sides, clogged distillation every six hours, collapse of the lime kiln, and even an explosion, on Christmas eve, of the last of the old boilers, which caused a complete shutdown of the factory.

But in just a few months, new boilers were installed, there were essential modifications made to the equipment and then the true production started already achieving the goal of the annual capacity of 6000 tons by 1938.

In 1935, the annual production reached only 925 tons of soda ash, as in 1939 would then rise to 7104 tons.

The quality of the first soda produced by the factory, when Solvay took over in the early 1930s, was very poor. The content of those first tons was low in carbonate, excessive in salt, and particularly high in iron, which gave it a reddish tone. However, it was Soda!

Revived with the modernization of the manufacturing of soda ash and the launch of the electrolytic factory in March 1938 for the production of caustic soda, sodium hypochlorite, and calcium chloride, Soda Póvoa was forced, only six years after its creation, to “swim” on its own.

After a few months since the outbreak of World War II, there was a forced cut in the ties with the headquarters in Brussels, thus, in practice, technical assistance and support from the “parent” company to its Portuguese “child” were suspended.

Starting from May 1940, after the relationship was interrupted, the factory was also unable to source from its usual suppliers, with the exception of Switzerland, Great Britain (although significantly reduced), and Spain (ruined by the Spanish Civil War of 1936-39).

In spite of that, the biggest threats can also turn out to be opportunities: World War I brought the initial equipment and the idea of taking advantage of it to Portugal; World War II forced the factory to move from adolescence to adulthood.

What few people may know is that for years the profits were nil, even registering negative results, due to two main reasons: the low productions, limited to domestic consumption; and the prices regulated by the government, that, in order to combat inflation, rarely allowed increases.

It was only in the 1950s that a balance in results was achieved, with some profitability appearing. From then on, the chronology is very rich and credit for it must be given to the people, the most precious asset.

1922 - Construction of an installation for the production of soda ash (sodium carbonate), by R. Touzet.

1934 - Acquisition by the Solvay group, with the creation of Soda Póvoa, SARL, a subsidiary of Solvay & Cie.

1938 - Assembly and start-up of the country's first salt electrolysis, and the Company began producing electrolytic caustic soda, calcium chloride, and sodium hypochlorite.

1940 - Start of production of sodium silicate and hydrochloric acid.

1942 - Start of exploitation of the Vialonga Quarry.

1945 - Start of production of liquid chlorine.

1957 - Start of the salt supply to the Factory, in the form of brine, through a pipeline originating from the salt-gem drillings in Matacães (Torres Vedras).

1963 - Entry into service of the sodium bicarbonate production plant.

1966 - Start-up of the sodium carbonate dense production plant.

1967 - Start of sodium chlorate production and refined salt production.

1974 - Investment in increasing the capacity of the soda ash plant.

1975 - Start-up of the new hydrogen peroxide and sodium perborate factories of Interox Portuguesa.

1976 - Entry into service of a new pipeline connecting Matacães to Póvoa, reducing the route.

1982 - Start-up of the new sodium hypochlorite plant.

1984 - Doubling of the sodium chlorate production capacity.

1986 - Entry into service of a demercurization plant. Supply of hydrogen to Ar Líquido.

1988 - Change of name from Soda Póvoa to Solvay Portugal - Produtos Químicos, SA.

1990 - Entry into service of membrane cells in chlorine electrolysis.

1992 - Construction of a bridge over the railway line for direct truck access. Start-up of the new hydrochloric acid production plant.

1993 - Solvay Portugal and Solvay Interox subscribe to the voluntary program Responsible Care®, promoted in Portugal by the chemical companies’ association.

1996 - Certification by IPQ of the quality assurance system for dense soda. First "Open Doors" event dedicated to the local community.

1998 - Stoppage of mercury electrolysis, demercurization, liquid chlorine, and calcium chloride.

1999 - Opening of the new Laboratory facilities.

2002 - Start-up of a natural gas cogeneration plant operated by Energin. Disinvestment on the sodium perborate production due to market reasons.

2003 - Solvay Portugal and Solvay Interox receive certification of their Quality Management System according to the requirements of the International Standard ISO 9001:2000.

2006 - Installation of a new reverse osmosis demineralization unit.

2007 - Entry into service of two new distillation groups in soda ash production. Doubling of the sodium bicarbonate production capacity.

2008 - Solvay Portugal and Solvay Interox facilities receive the Integrated Pollution Prevention and Control Environmental License.

2014 - Restructuring of activities for competitiveness and market reasons, with closure, dismantling, and demolition of constructions of the units of sodium and chlorinated products.

By the end of the first trimester of 2021, a new cycle began in the Company's history, marked by renewed ambition and the launch of new projects to build the future.

The acquisition of Solvay Portugal, which had been negotiated between its new shareholder, ALGORA, and the Solvay group, was completed. This had been announced in September 2020, at the time of the signing of the respective share purchase agreement. On March 31, 2021, ALGORA took control of Solvay Portugal and this company changed its name to HyChem - Produtos Químicos, SA.

ALGORA Sustainable Investments, SGPS, SA - the new controlling shareholder of HyChem - is a holding company established in a joint venture between:

• A4F SGPS - a biotechnology group holding company with significant R&D activities, specialized in providing technology for algae production, installing macro and microalgae production units to capture CO2 and use industrial effluents, as well as developing technologies and processes for microorganism fermentation;

• and Green Aqua - a group holding company specialized in investing in macro and microalgae production and biorefining units, as well as other biobased products.

Both these groups, associated with ALGORA,z have exclusively Portuguese capital and are based in Portugal.

At the same time, the composition of the management bodies was changed, with a new Board of Directors and a new Auditor being appointed by the new shareholders.

The agreement signed in March 2021 focused on the acquisition of all the shares representing the share capital of Solvay Portugal. Later, in December of the same year, HyChem changed its name to HyChem, Sustainable Chemistry, SA, with this change becoming an important milestone in the Company's strategy.

At the time of the share acquisition, the company's main assets were the Sodium Chlorate and Hydrogen production unit, the entire industrial park in Póvoa de Santa Iria, and the salt mine in Torres Vedras and its concession.

Following the acquisition, the new shareholders retained all jobs and all the people who were part of the company, whom they rely on to execute a new growth strategy based on sustainability principles.

The new management decided to assign the activities related to administrative and support services, namely personnel, financial services, and information systems, to the Shared Services company belonging to the universe of the new shareholders - Assergest, Lda.

Similarly, the acquisition required a change in the Company's commercial model, which until then was exclusively managed by the Solvay group's corporate structure, which acquired the Company's products and marketed them to end customers. As a result, the new management took over the commercial activity management directly, and HyChem began to sell its products directly.

Looking back, we can only be impressed with the path that Póvoa de Santa Iria and HyChem have travelled together.

The first, a humble settlement, was elevated to a parish (1916), a town (1985) and a city (1999) in less than a century, and now has over 30,000 inhabitants.

The second had a troubled childhood, but grew up and, upon reaching adulthood, became a source of wealth for the municipality of Vila Franca de Xira and a strong support for the development of numerous Portuguese industries.

With our employees, customers and suppliers, public decision-makers and regulators, as well as civil society and the local community, all focused on generating shared value, we are determined to face the challenges and build a sustainable future.